IOSI-01 – online iron ratio

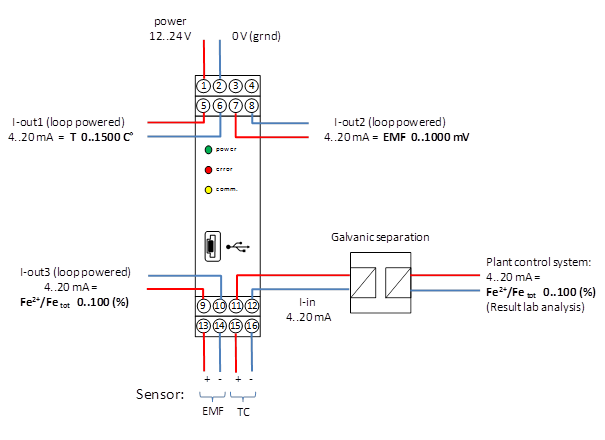

The standard 4..20 mA outputs of the oxygen sensor interface IOSI-01 are glass melt temperature (on I-out1), EMF (on I-out2) and logpO2 (on I-out3). However, the furnace operator may prefer a continuous iron-ratio (Fe2+/Fetot) of the cold glass on I-out3.

Log pO2 of the glass melt is a (more or less) scientific quantity. Operators are often used to express the redox state as the Fe2+/Fetot-ratio of the cold glass product. The iron ratio is the result of the (daily) off-line laboratory redox analysis of a glass sample by means of spectroscopy. The same parameter as sensor output will make the on-line redox measurement more understandable to the operator and will prevent miscommunication between him and the laboratory personnel about set-point and operation window.

At the start of the on-line iron ratio output, the IOSI must be calibrated by giving the most actual laboratory Fe2+/Fetot-ratio of the cold glass on the I-in terminal of the IOSI as a 4..20 mA signal. From thereon, the IOSI gives the on-line Fe2+/Fetot-ratio of the cold glass on I-out3, which is calculated from the measured oxygen cell EMF changes and temperature changes since the calibration with the laboratory iron ratio took place.

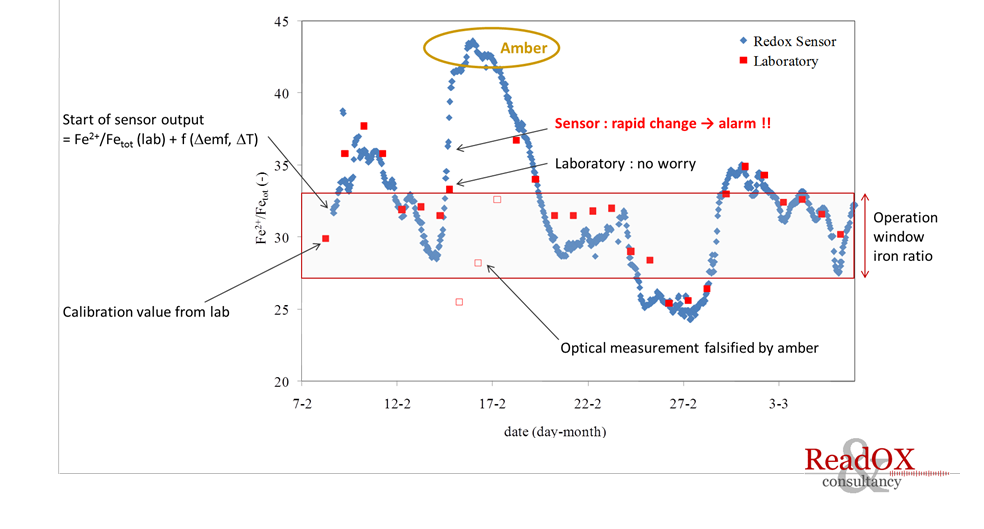

The graph below shows on-line iron ratio measured by a redox sensor in the feeder channel of a furnace melting emerald green container glass. After calibration of the IOSI with the iron ratio measured in the laboratory by means of a fotospectrometer, the on-line iron ratio output can be started. It can be seen that iron ratio measured by the sensor corresponds well with the daily analysed iron ratio from the laboratory, without recalibration of the IOSI since the start of the measurement. The added value of an on-line redox sensor can immediately be recognised: the iron ratio from the laboratory is usually only available once per 24 hours as a single data point, whereas the continuous sensor signal gives information on the rate of change and the direction (reduced/oxidised) of the iron ratio every moment of the day!