Over the past decades, the glass industry has succeeded to reduce operational costs and to improve product quality significantly as a result of a better understanding of the industrial melting process and improved production technology methods and materials. Although the use of in-line oxygen sensors to measure and control glass melt and glass product properties is recognized as an important, production improving technology, it lagged behind. This is mainly due to the difficulty of an accurate measurement for extended times in the usually extremely hot and corrosive glass melt or atmosphere.

Over the past decades, the glass industry has succeeded to reduce operational costs and to improve product quality significantly as a result of a better understanding of the industrial melting process and improved production technology methods and materials. Although the use of in-line oxygen sensors to measure and control glass melt and glass product properties is recognized as an important, production improving technology, it lagged behind. This is mainly due to the difficulty of an accurate measurement for extended times in the usually extremely hot and corrosive glass melt or atmosphere.

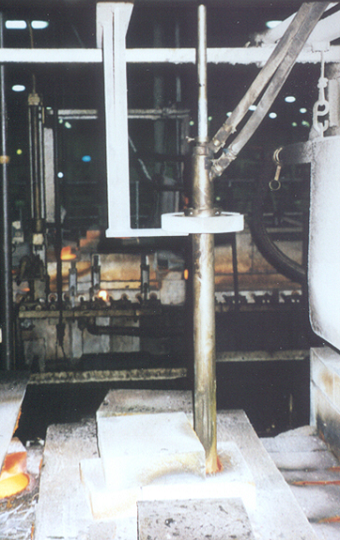

In the present situation temperature is often the only parameter which is continuously measured in the glass melt and combustion atmosphere of an industrial glass production furnace. However, research on glass chemistry during the past decades showed that besides the glass melt and atmosphere temperature, the oxygen activity of melt and atmosphere are also very important production parameters that should be continuously available during the industrial glass production process. By supplying innovative oxygen sensors for both melt and atmosphere, Read-Ox is able to offer this measuring technology to the glass industry!