Tin Bath Hydrogen Sensor

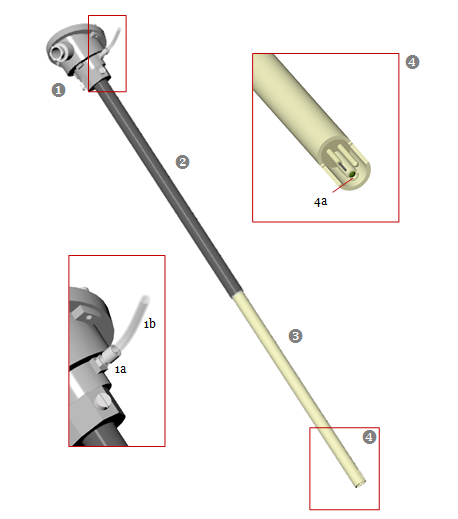

A hydrogen sensor was recently developed for the in-line measurement of the partial hydrogen pressure in the molten tin or atmosphere. The sensor is based on an indium-doped CaZrO3 solid electrolyte cell (4a) and continuously measures the hydrogen activity of the tin melt or the %H2 in the atmosphere up to 900ºC. The internal of the Indium-doped CaZrO3 cell must be flushed with a reference gas (gas inlet 1a) with a defined hydrogen content (e.g., 1%H2 in N2).

Especially at high hydrogen levels in the hot end section of the tin bath, formation of hydrogen gas bubbles in the molten tin may damage the bottom surface of the ribbon. Also partial or full oxy-fuel firing in the glass melting sections may eventually lead to the formation of hydrogen bubbles in the tin bath. Higher water levels in the combustion atmosphere as a result of oxy-fuel firing leads to a higher water content of the glass melt. Water may diffuse out of the glass ribbon into the tin melt and dissociates into H2 and O2 gas under the reducing circumstances in the tin bath. The consequently higher hydrogen level in the tin may lead to formation of hydrogen bubbles under the glass ribbon.